Quality | Precision parts

Quality

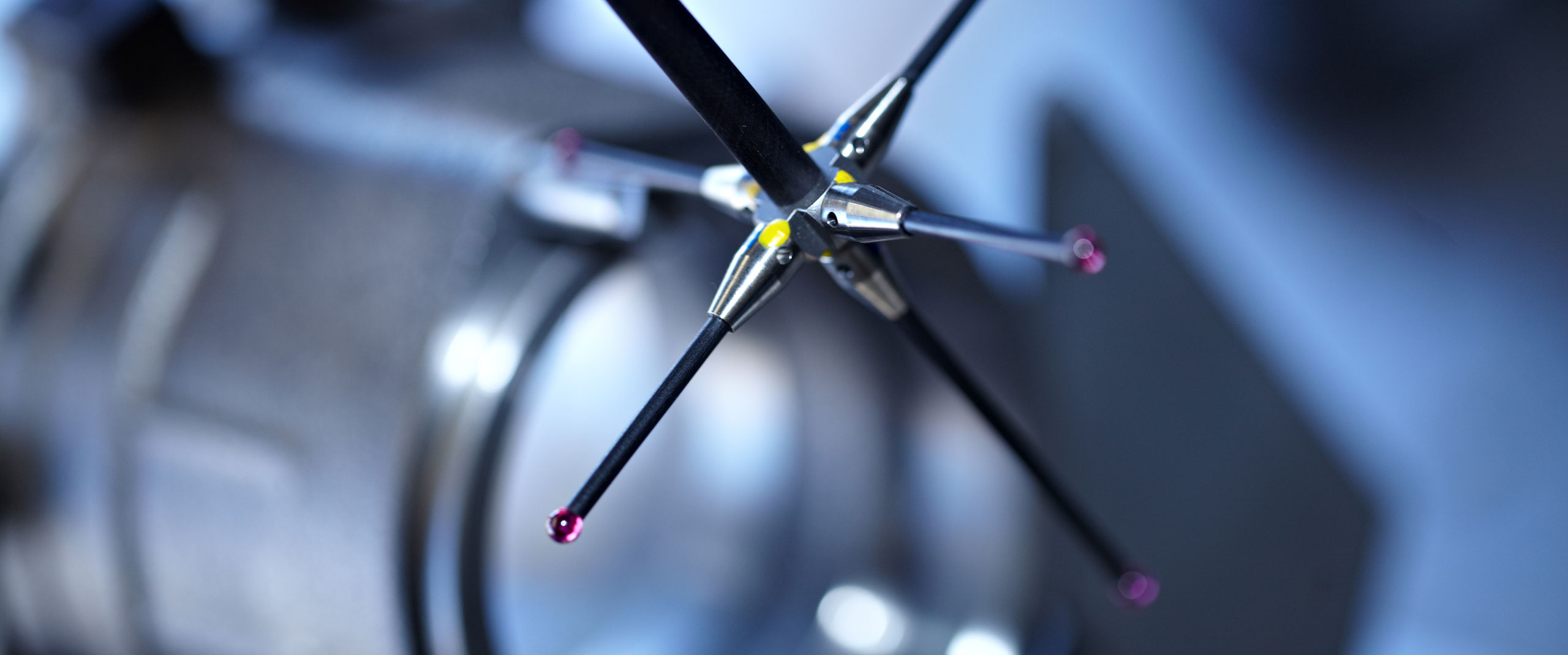

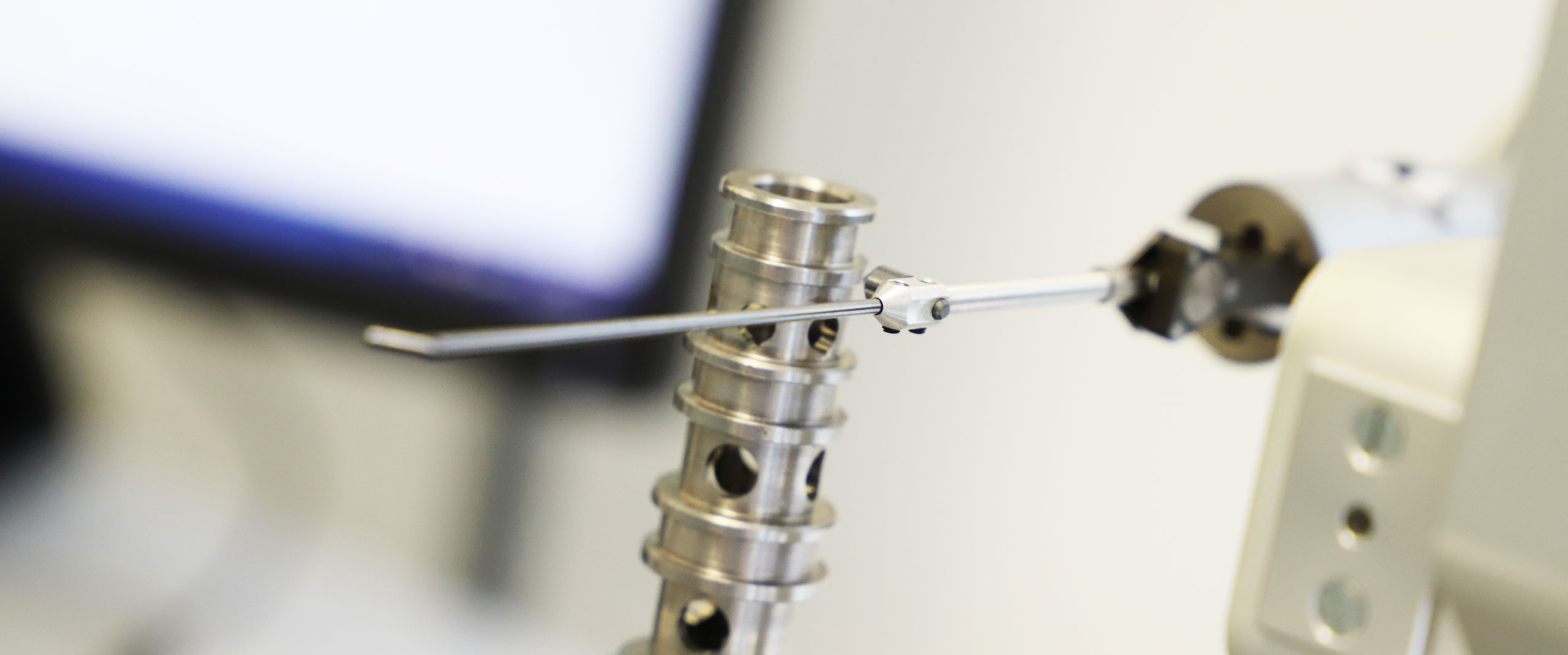

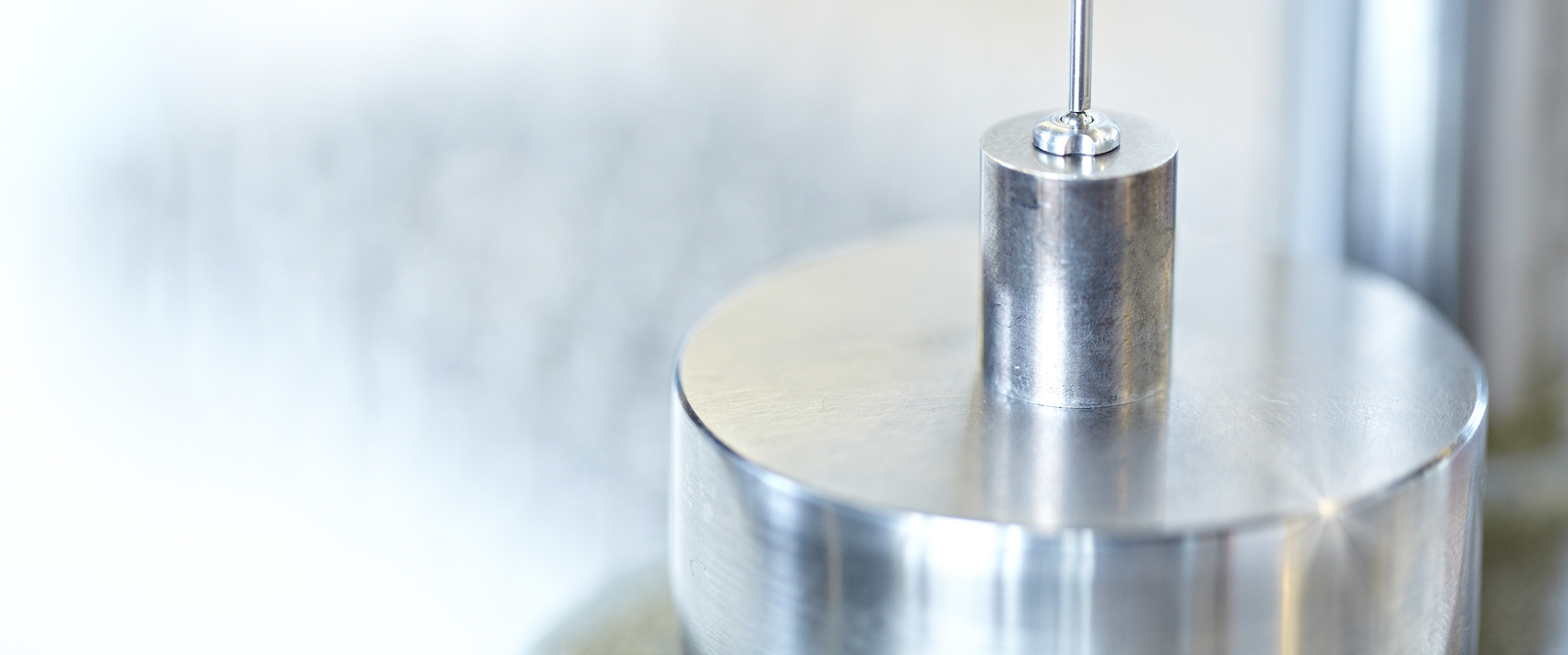

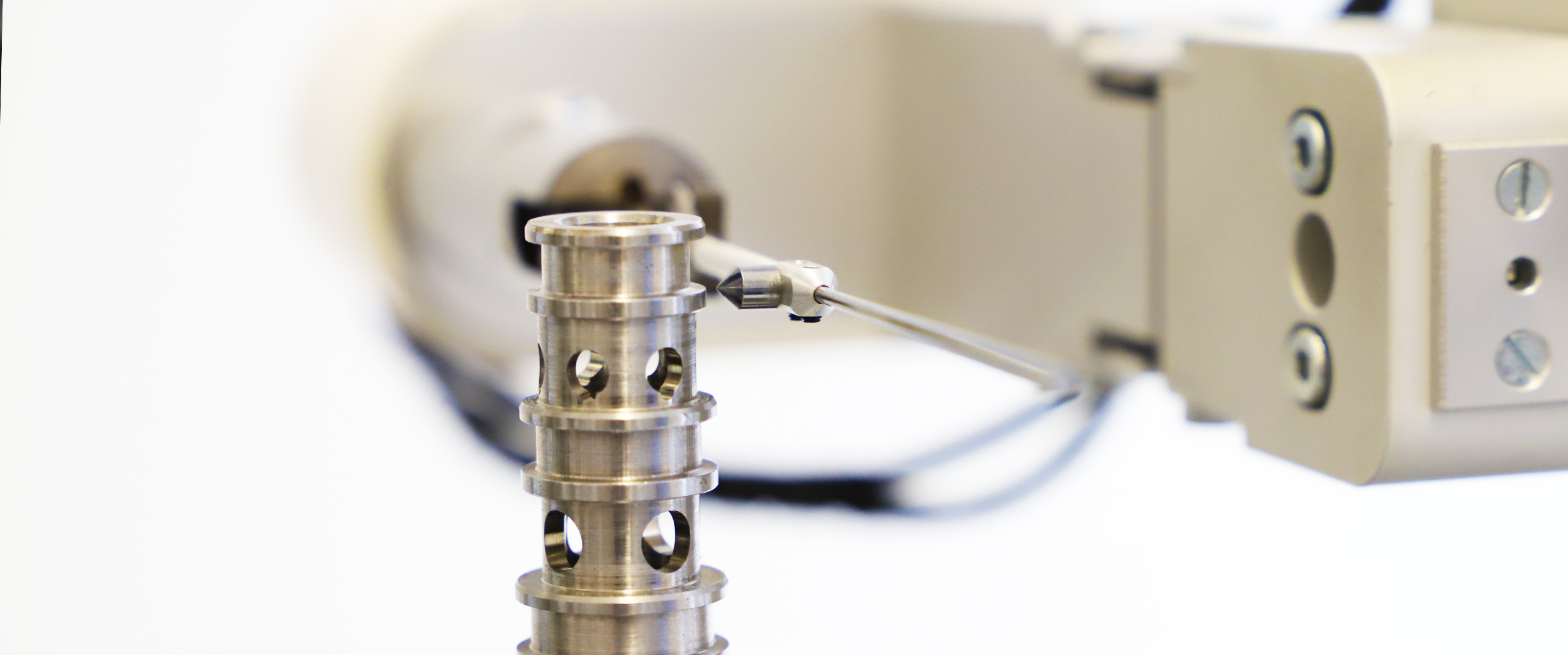

Everything revolves around the exact manufacture of precision turned parts, especially if the tolerances are strict. That’s why zero error policies are essential to our quality and hence our success. Our specialised employees perform initial piece approval and in-line tests on each production batch using the latest optical and tactile measuring machines. In order to ensure our impeccable quality, we operate active and comprehensive quality management to detect and eliminate potential errors as quickly as possible and to ensure that they cannot reoccur in the future.

We invest steadily in a wide variety of high-tech testing systems that cover and document all measurements of the various production processes:

- QPT contour measuring equipment

- DELTRONIC projector

- TESA height measuring device

- MAHR surface measuring device

- ZEISS measuring machine

- VICI optical wave testing device

It goes without saying that we are certified according to DIN EN ISO 9001:2015, DIN EN ISO 14001:2015 and DIN EN ISO 50001:2018.

You will find our current ISO certificates in the Download tab. To the Downloads